| Sign In | Join Free | My gimpguru.org |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gimpguru.org |

|

Place of Origin : China

Brand Name : Sanxin

Certification : ISO

MOQ : 1 piece

Price : Negotiable

Packaging Details : Safety Packing

Delivery Time : 15~45 Days

Payment Terms : L/C, T/T, Western Union

Supply Ability : 10-50000pcs/month

Model Number : SX2182

Name : Internal Hole Punch Slotting Punch Set

Categories : Tungsten carbide punch set

Grade : YG10, YG15, K30, K20, P10...

Surface : Mirror polishing

Hardness : HRA 90-92

Customization : Available

Appliction : Small Core Working Parts

Applications : Metal Stamping, Punching, Forming

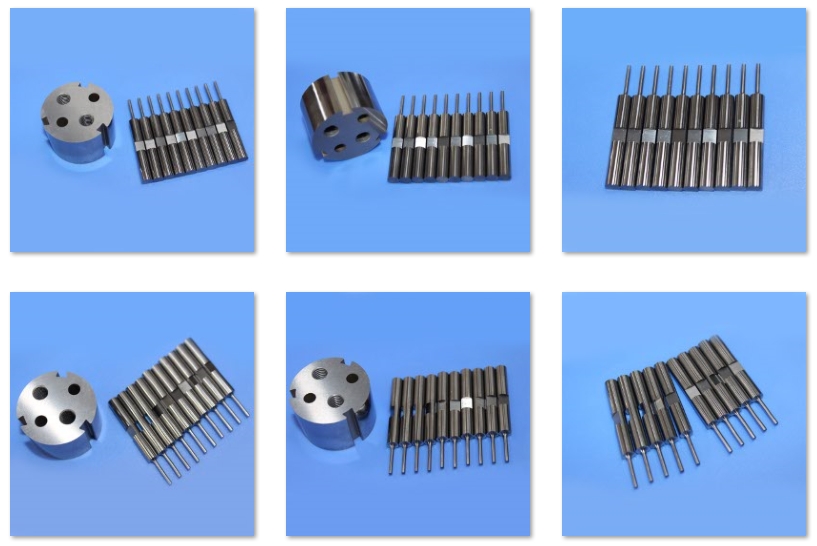

Precision Stamping Processing Internal Hole Punch Slotting Punch Set

The internal hole punch slotting punch set is a critical tool used in metal processing, primarily for cutting grooves or slots on workpiece surfaces. This set is typically made of high-strength alloy steel or special alloy materials, capable of providing reliable cutting and machining solutions in high-load and precision machining environments.

Product Features

| Property | Range |

| Grain Size (μm) | 0.4-2.0 |

| Cobalt Content (% Co) | 6-20 |

| Density (g/cm³) | 13.96-14.85 |

| Hardness (HRA) | 86-93 |

| Flexural Strength (MPa) | 3200-4500 |

| Young's Modulus (GPa) | 570-620 |

|

|

Precision Stamping Processing Internal Hole Punch Slotting Punch Set Images |